## From Noodles to Nanochips: Vietnam’s Silicon Dream Takes Shape Vietnam, a nation synonymous with fragrant pho and vibrant silk, is quietly making waves in a world dominated by tech giants. Forget rice paddies; the country is now cultivating a future powered by semiconductors, attracting international investment and fostering a wave of homegrown innovation. A recent GlobeNewswire report shines a light on this burgeoning industry, revealing how Vietnamese enterprises are leveraging global support to break into the semiconductor sphere. Join us as we delve into this exciting story, exploring the ambitious vision driving Vietnam’s silicon dream and the challenges they face in becoming a major player in the global semiconductor landscape.

Inauguration and Commencement of Operations at the National Innovation Center

On October 1, 2024, the ATP Semiconductor Chip Technician Training Center was officially inaugurated and commenced operations at the National Innovation Center (NIC) located within the Hoa Lac High-Tech Park in Hanoi, Vietnam. The inauguration marked a significant milestone for Vietnam’s semiconductor industry, as it aligns with the broader strategy to establish Vietnam as a key player in the global semiconductor value chain. The NIC, as a focal point, not only serves as a hub for innovation and technology development but also underscores the government’s commitment to fostering an environment conducive to technological advancement and international collaboration.

The location of the NIC within the Hoa Lac High-Tech Park is strategic, given the park’s role as a hub for high-tech industries and its proximity to major research institutions and academic centers. This strategic positioning facilitates a robust ecosystem for knowledge transfer, research, and development, thereby enhancing the competitiveness of Vietnamese enterprises in the semiconductor sector.

Overview of CT Semiconductor’s Broader Activities and Initiatives

CT Semiconductor, a member of the CT Group, is a leading force in the semiconductor industry, with its broader activities encompassing the establishment of three OSAT plants, two R&D centers, and two customer service centers in key global technology hubs such as Silicon Valley and Phoenix, Arizona. These comprehensive initiatives are part of a larger strategy to build a robust semiconductor industry in Vietnam, supported by the government’s strategic plans.

CT Semiconductor’s approach emphasizes the importance of independent technology development, which is crucial for long-term sustainability and global competitiveness. The company’s commitment to innovation is evident in its focus on advanced training programs, research and development, and the integration of modern technology into its operations.

Training and Development Programs

One of the key initiatives undertaken by CT Semiconductor is the “Train the Trainer” program, which aims to equip key personnel with specialized skills in semiconductor chip assembly, testing, and packaging. This program is pivotal in building a skilled workforce that can support the rapid growth of the semiconductor industry in Vietnam. The training is provided by experienced engineers from various countries, ensuring that the knowledge and expertise are of the highest international standards.

Another essential aspect of the training program is the hands-on experience provided to interns and final-year electronics students. These interns are given the opportunity to work with the latest chip inspection machines, thereby gaining practical experience and familiarizing themselves with various types of semiconductor chips. This hands-on approach is instrumental in bridging the gap between theoretical knowledge and practical application, equipping the next generation of engineers with the skills necessary to innovate and lead the industry.

Technology and Innovation: The ATP Semiconductor Approach

CT Semiconductor’s independent technology approach is centered around the development and deployment of advanced semiconductor testing and manufacturing technologies. A prime example of this is the introduction of the AMB5600 semiconductor circuit and component testing machine. This machine is a first-of-its-kind integrated into a training system in Vietnam and is designed to support research, training, and operational efficiency, ensuring that the training center remains at the forefront of innovation.

The independent technology approach, championed by CT Semiconductor, fosters a sustainable semiconductor industry in Vietnam. By focusing on self-reliance and innovation, the company aims to avoid the pitfalls of merely following trends and instead develops a strategy driven by local expertise and global talent. This vision is in line with the broader objectives of the Vietnamese government, as outlined in Prime Minister’s Decision No. 1018/QD-TTg, which underscores the strategic importance of developing a robust semiconductor industry in the country.

Global Trends in Advanced Packaging Technologies

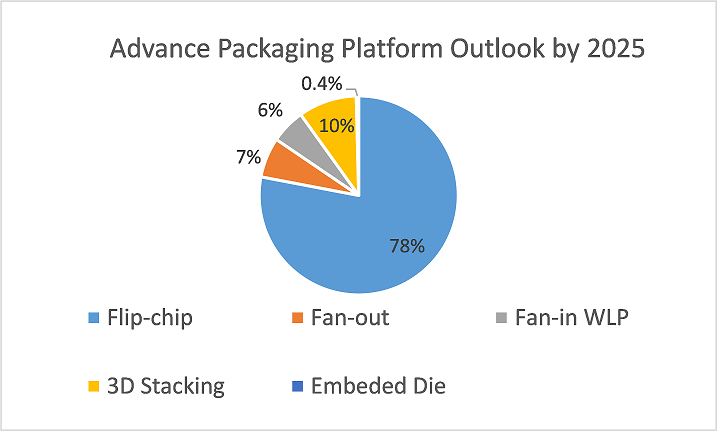

Advanced packaging technologies are at the forefront of the semiconductor industry, driving global economic recovery and technological advancements. The industry is witnessing a significant shift as foundries, substrate/PCB suppliers, and Electronic Manufacturing Service (EMS) providers enter the packaging business, altering the competitive landscape. Innovations in packaging technologies, such as heterogeneous integration and wafer-level packaging, have ushered in a new era of semiconductor solutions that address the growing demand for high-performance, low-power, and miniaturized devices.

One of the key trends in advanced packaging technologies is the increase in the size of silicon wafers from 100mm to 300mm, which has led to a reduction in manufacturing costs by 20-25%. This shift is a response to the need for more efficient and cost-effective manufacturing processes, aligning with the broader goal of meeting the escalating demands of the semiconductor industry. Additionally, the miniaturization of devices and the increased adoption of Micro-Electro-Mechanical Systems (MEMS) have driven the demand for embedded die packaging, a technology that enables the integration of multiple chips into a single package, enhancing performance and efficiency.

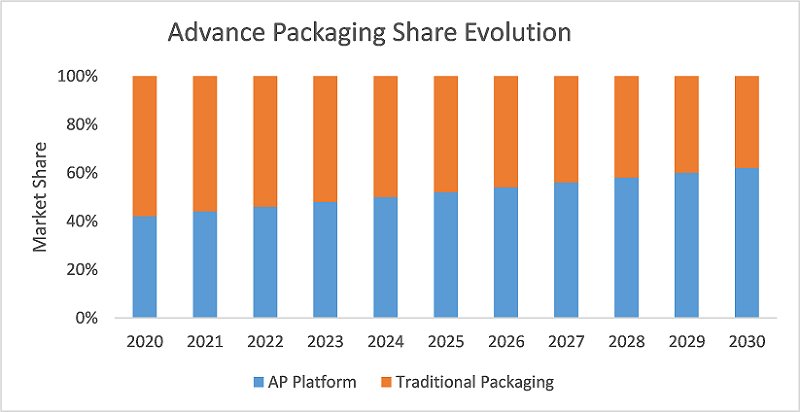

- Advanced Packaging Market Share and Forecast: The advanced packaging market is expected to account for more than 60% of the semiconductor packaging market by 2030, a significant increase from the 40% share held in 2020.

- Innovations and Partnerships: Collaborations such as Siemens Digital Industries Software’s partnership with Advanced Semiconductor Engineering, Inc. (ASE) to evaluate complex IC package assemblies, and Samsung’s introduction of the eXtended-Cube (X-Cube) technology, showcase the industry’s commitment to pushing the boundaries of semiconductor packaging technology.

Key Players and Competitive Landscape

The advanced packaging market is highly competitive, with a few major players holding a significant share. Intel, Samsung, TSMC, ASE, SPIL, Amkor, PTI, JCET, Nepes, and Chipbond collectively hold approximately 75% of the global market. These companies have built sustainable competitive advantages through continuous innovation, leading to the development of differentiated products and solutions that cater to a wide range of applications.

The industry’s competitive landscape is evolving, with a significant shift in the assembly and packaging business. Traditionally dominated by OSATs and Integrated Device Manufacturers (IDMs), the market now includes new entrants such as foundries and EMS companies, who are leveraging their expertise and resources to enter the packaging and assembly business. This expansion of the competitive landscape is expected to drive innovation and competition, ultimately benefiting the industry and consumers.

Case Studies and Industry Collaborations

Several case studies highlight the impact of strategic partnerships and collaborations in advancing the semiconductor packaging industry. For instance, the partnership between Siemens Digital Industries Software and ASE to evaluate multiple complex IC package assemblies has resulted in more robust and efficient packaging solutions. Additionally, Samsung’s silicon-proven 3D IC packaging technology, eXtended-Cube (X-Cube), has set new benchmarks for advanced packaging, particularly in terms of performance and cost efficiency.

The integration of two Universal Instruments Fuzion Platform production lines by Synapse Electronique in Quebec, Canada, represents another significant milestone. This integration has enabled the company to enhance its production capabilities and meet the growing demand for complex semiconductor devices. These collaborations demonstrate the evolving role of OSATs, IDMs, and EMS companies in the semiconductor ecosystem, highlighting the importance of strategic alliances and partnerships for technological advancement and market leadership.

Implications for Vietnam’s Semiconductor Industry

Vietnam’s semiconductor industry is poised for a significant transformation as the country seeks to establish itself as a key player in the global semiconductor market. The inauguration of the ATP Semiconductor Chip Technician Training Center and the broader initiatives by CT Semiconductor represent a strategic move towards developing a self-reliant semiconductor sector. The training center’s presence at the National Innovation Center in Hoa Lac High-Tech Park is indicative of the government’s support and the industry’s commitment to fostering a robust ecosystem for semiconductor technology development.

The strategic investments in specialized facilities and equipment are crucial for the advancement of the semiconductor industry in Vietnam. Firms specializing in assembly, packaging, and testing typically invest around 15% of their annual revenues into facilities and equipment, a figure that underscores the importance of continuous capital investment to sustain and enhance production capabilities. The back-end process is less capital-intensive compared to the front-end process, yet it requires significant labor and expertise to ensure high-quality manufacturing. The integration of advanced packaging technologies into the Vietnamese semiconductor industry is expected to drive further technological advancements and operational efficiencies.

Strategic Investments and Technological Advancements

The integration of advanced packaging technologies, such as the AMB5600 semiconductor circuit and component testing machine, is a testament to Vietnam’s commitment to leveraging cutting-edge technology. The AMB5600, an advanced testing machine, plays a pivotal role in ensuring that Vietnam’s semiconductor industry can meet global standards and compete on a global scale. This technology not only enhances the efficiency and accuracy of semiconductor testing but also positions Vietnam as a hub for technological innovation and advancement.

Strategic investments in specialized facilities and equipment are critical for the growth of the semiconductor industry in Vietnam. These investments are not only essential for maintaining competitiveness but also for ensuring quality and reliability in semiconductor manufacturing. The AMB5600 testing machine, alongside other specialized equipment, is a prime example of the kind of technological advancements that are necessary to support the industry’s growth and expansion.

Government and Industry Collaboration

The Vietnamese government has been proactive in supporting the semiconductor industry through various initiatives aimed at fostering a conducive environment for technological advancement and innovation. This support is crucial for the sustainable development of the industry. The government’s commitment is evident in its strategic planning and initiatives such as the ATP Semiconductor Chip Technician Training Center. The government’s vision is to create a collaborative ecosystem that involves international collaboration, technological transfer, and knowledge sharing, thereby enhancing the industry’s capabilities and global competitiveness.

For the semiconductor industry in Vietnam to thrive and achieve sustainable growth, there is a need for fair and balanced support from the government. This support should be in the form of policies that facilitate international collaboration, technological transfer, and the creation of a skilled workforce. The government’s role is to ensure that the semiconductor industry benefits from a favorable regulatory environment that encourages innovation, investment, and collaboration.

Challenges and Opportunities Ahead

The semiconductor industry in Vietnam faces several challenges, including mastering cutting-edge technology, attracting global talent, and ensuring a steady influx of investment. Ensuring that these challenges are addressed is essential for the industry’s long-term success. The industry must focus on developing a skilled workforce and fostering a culture of innovation and technological advancement. Through strategic collaborations and international partnerships, Vietnam can overcome these challenges and emerge as a leader in the global semiconductor market.

The path forward for Vietnam’s semiconductor industry involves a strategic focus on mastering advanced packaging technologies and integrating these technologies into the supply chain. This approach not only enhances the industry’s competitiveness but also positions Vietnam as a preferred destination for semiconductor manufacturing and innovation. By leveraging the knowledge and expertise of global partners, Vietnam can overcome the current limitations and establish a robust and sustainable semiconductor industry.

Conclusion

In conclusion, the article highlights the remarkable progress Vietnamese enterprises have made in advancing semiconductor technology with the support of international partners. Key takeaways from the article include the significant investments made by foreign companies in Vietnam’s semiconductor industry, the establishment of joint ventures and research collaborations, and the resulting growth in domestic production and exports. These developments have not only strengthened Vietnam’s position as a key player in the global semiconductor market but also created new opportunities for domestic companies to innovate and compete on a global scale.

The significance of this trend cannot be overstated, as it underscores the importance of international cooperation and collaboration in driving technological advancements and economic growth. As the global semiconductor industry continues to evolve, Vietnam’s strategic location and favorable business environment make it an attractive destination for foreign investment and innovation. Looking ahead, it is likely that we will see even more investment and collaboration in the industry, driving further growth and development in Vietnam.

As we look to the future, it is clear that Vietnam’s semiconductor industry is poised for continued success and growth, driven by the convergence of technological innovation, international cooperation, and economic dynamism. As the country continues to advance and innovate, it is essential that we remain committed to fostering a collaborative and supportive environment that enables domestic enterprises to thrive and compete on the global stage. As we move forward, the possibilities are endless, and the future of Vietnam’s semiconductor industry holds immense promise for economic growth, technological progress, and global competitiveness.