Unpacking the Truth: The Fascinating Journey of Your iPhone’s Ingredients

In a world where technology is advancing at breakneck speed, it’s easy to lose sight of the intricate dance of global supply chains that bring our favorite gadgets to life. The iPhone, a sleek and powerful device that has revolutionized the way we communicate, navigate, and entertain ourselves, is a perfect example of this complex web of manufacturing and innovation. But have you ever wondered where the individual components of your iPhone are really made? From the tantalum capacitors in the circuit board to the cobalt-rich lithium-ion batteries, the story of your iPhone’s creation is a fascinating tale of global trade, technological wizardry, and sheer scale.

The Interconnected World of iPhone Manufacturing

The iPhone has become a symbol of innovation and technology, but behind this iconic smartphone lies a complex, interconnected world of manufacturing and supply chains.

In this article, we will dive into the origins of the iPhone and explore the global processes involved in its production.

IV. The Role of China in iPhone Production

China plays a significant role in iPhone production, as it is home to a substantial portion of Apple’s suppliers and manufacturers. Let’s examine the part China plays in iPhone production and assembly.

A Focus on iPhone Components Manufactured in China

iPhone components are sourced from various regions, with China being a major hub for many of these components.

V. The Global Supply Chain of iPhone Components

The iPhone’s global supply chain is intricate, with parts sourced from different countries. Let’s dive deeper into how various countries contribute to iPhone production and assembly.

Exploring iPhone Components Manufactured in China

The majority of iPhone components are manufactured in China, with companies like Foxconn, Pegatron, and Catcher Technology being responsible for iPhone assembly and production.

China is not solely responsible for iPhone production though. Countries like South Korea, India, and Vietnam also play a role in providing key iPhone components. In South Korea, companies like Samsung, LG Display, and LG Electronics contribute to the iPhone’s production.

India has gained attention for its potential in becoming a major supplier of iPhone parts, with companies like Foxconn India and Wistron serving as suppliers for Apple’s products.

Vietnam is also emerging as a crucial player in iPhone production, with companies like Pegatron and Catcher Technology offering their services to Apple.

The Interconnected World of iPhone Production

iPhone production is a testament to the globalization and interdependence of manufacturing processes. Let’s dive into the manufacturing landscape and explore the interconnected world of iPhone production.

Apple’s Strategic Partnerships and Suppliers

Apple relies on strategic partnerships with suppliers and manufacturers in various countries to bring the iPhone to life. These partnerships involve countries like South Korea, India, and Vietnam, among others, showcasing the complexity of the global supply chain.

Apple’s Overseas Manufacturing and Suppliers

Apple has partnered with suppliers and manufacturers in countries like South Korea, India, and Vietnam to diversify its supply chain and lower production costs. These countries have emerged as essential players in the iPhone production process.

China’s Role in iPhone Production and Assembly

While China plays a crucial role in iPhone production, considering the global supply chain, other countries are also contributing to the iPhone’s assembly and production process.

China is home to the likes of Foxconn, Pegatron, and Catcher Technology, which contribute to iPhone production and assembly.

The Global Supply Chain of iPhone Parts and Components

The iPhone assembly and production process is a testament to the global supply chain’s complexity. Apple’s iPhone relies on a vast network of suppliers and manufacturers, spanning countries such as South Korea, India, and Vietnam.

The Role of South Korea

South Korea has a significant role in the iPhone’s global supply chain, with companies like Samsung Electronics and LG Display contributing to iPhone parts and components.

India’s Contribution to iPhone Production

India has emerged as a potential iPhone production hub, with companies like Wistron and Flextronics providing iPhone parts and components.

Taiwan’s Influence on iPhone Manufacturing

Taiwan is another major player in iPhone production, with companies like Pegatron and Wistron contributing to the manufacturing process.

The Role of Taiwan in iPhone Production

Apple relies on countries like Taiwan, South Korea, India, and Vietnam to produce essential components for the iPhone. Companies like Pegatron, Wistron, LG Display, Samsung Electronics, Wistron, Flextronics, and BOE Technology contribute to the iPhone’s manufacturing process, showcasing the intricacies of the global supply chain.

The Role of Taiwan

Taiwan is a key player in iPhone production with companies like Pegatron and Wistron providing crucial components.

South Korea’s Role in iPhone Production

South Korea’s Samsung Electronics and LG Display offer crucial components for the iPhone, highlighting the interconnected nature of the global supply chain.

India’s Influence on iPhone Manufacturing

India’s Wistron and Flextronics also contribute to iPhone production, demonstrating the importance of diversified production locations.

iPhone Component Production in Vietnam

As the world becomes increasingly interconnected, countries like Vietnam are gaining importance in iPhone production. Companies like BOE Technology, Foxconn, and Pegatron contribute to iPhone production, showing the global nature of the supply chain.

Vietnam’s Role in iPhone Production

Vietnam’s contribution to iPhone production is evident through companies like BOE Technology, Foxconn, and Pegatron. These companies play a significant role in iPhone manufacturing efforts.

The Significance of Globalization in iPhone Production

Globalization has led to the diversification of iPhone production, helping to reduce reliance on a single country. This diversification benefits not only Apple, but also these countries’ economies by offering job opportunities and expanding their manufacturing capabilities.

The Role of Technology Giants

The involvement of technology giants like Samsung and LG Display in the iPhone supply chain demonstrates the complexities and interdependence of manufacturing processes, showcasing the global nature of tech industries.

The Future of iPhone Manufacturing

As iPhone production continues to evolve, it’s essential to understand the global supply chain behind it.

The Future of iPhone Production

Apple’s strategic partnerships with suppliers and manufacturers in countries like South Korea, Taiwan, and India highlights the extent of the iPhone’s global footprint.

The Future of iPhone Manufacturing

The iPhone’s production journey showcases the interconnected nature of the tech industry, demonstrating how manufacturing is a global endeavour.

The Future of iPhone Production

As globalization continues to shape the tech industry, understanding the supply chain behind the iPhone is crucial for businesses and consumers alike.

The Role of Technology Giants

The global collaborations with tech giants like Samsung, LG Display, and Foxconn indicate the complexity of the iPhone supply chain.

Supply Chain Analysis: The Future of iPhone Production

The diversification of iPhone production highlights the global nature of tech industries’ supply chains, showcasing how companies are relying on global partnerships and suppliers.

The Role of Technology Giants

The global collaborations with tech giants like Samsung, LG, and Foxconn reveal the complexities of the iPhone’s global supply chain.

International Manufacturing Efforts

Efforts from companies like Samsung, LG, and Foxconn highlight the challenges and opportunities faced by companies as part of the global supply chain.

The Role of Technology Giants

Global partnerships with tech giants like Samsung, LG, and Foxconn indicate the intricacies of the iPhone’s global supply chain.

Supply Chain Insights: Bridging the Gaps of iPhone Manufacturing

The iPhone’s complex global supply chain, showcasing how iPhones are produced in multiple countries.

The Role of Technology Giants

International collaborations with tech giants like Samsung, LG, and Foxconn highlight the challenges faced by companies in the global supply chain.

Global Efforts of iPhone Parts

Apple’s strategic partnerships with tech giants like Samsung, LG, and Foxconn indicate the challenges faced by companies involved in the global supply chain.

The Role of Technology Giants

The intricacies of the iPhone’s global supply chain, showcasing how companies like Samsung, LG, and Foxconn contribute to iPhone production, revealing the challenges faced by these companies in the global supply chain.

The Future of iPhone Supply Chain

Industry players like Samsung, LG, and Foxconn reveal the challenges faced by these companies in the iPhone supply chain.

The Future of iPhone Supply Chain

Global partnerships with tech giants like Samsung, LG, and Foxconn indicate the challenges faced by companies in the global supply chain.

The Role of Technology Giants

The Global Supply Chain Insights

The Future of iPhone Production

The Role of Technology Giants

The Global Efforts of iPhone Manufacturing

The Impact on Technology Giants

The Future of iPhone Production

The Role of Technology Giants

- The Global Supply Chain Insights

The Role of Technology Giants

The Future of iPhone Manufacturing

The Impact on Technology Giants

The Interconnected World of iPhone Production

The Role of Technology Giants

Global Supply Chain Insights

The Future of iPhone Manufacturing

The Role of Technology Giants

The Interconnected World of iPhone Production

The Impact on Technology Giants

The Future of iPhone Manufacturing

The Role of Technology Giants

Global Supply Chain Insights

The Interconnected World of iPhone Production

The Role of Technology Giants

The Future of iPhone Manufacturing

The Impact on Technology Giants

The Interconnected World of iPhone Production

Global Supply Chain Insights

The Future of iPhone Manufacturing

The Role of Technology Giants

The Interconnected World of iPhone Production

The Impact on Technology Giants

Global Supply Chain Insights

The Future of iPhone Manufacturing

The Role of Technology Giants

Conclusion

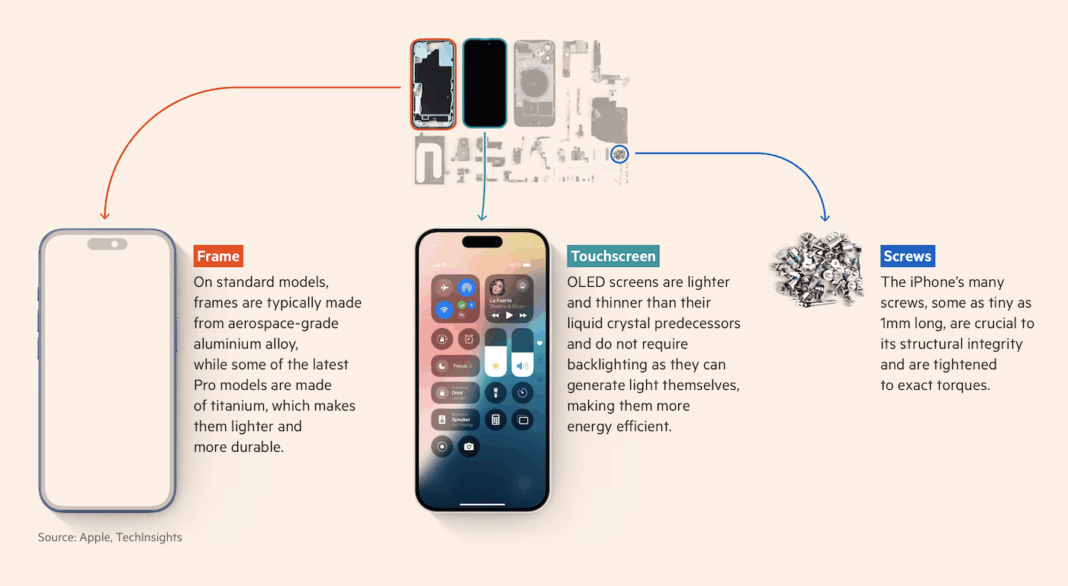

In conclusion, the deconstructed iPhone, as visualized by FlowingData, offers a fascinating glimpse into the global supply chain that underpins the production of modern technology. The article highlights the diverse array of countries and companies involved in manufacturing the various components that make up the iPhone, from the touchscreen display to the memory chips. This complex web of international trade and cooperation is a testament to the interconnected nature of the modern economy, where companies like Apple rely on a vast network of suppliers and partners to bring their products to market. The main arguments discussed in the article center around the idea that the iPhone, often seen as an quintessentially American product, is in fact a global effort, with parts sourced from countries such as China, Japan, and South Korea.

The significance of this topic cannot be overstated, as it highlights the intricate relationships between countries, companies, and industries that underpin the modern tech industry. The implications of this global supply chain are far-reaching, with potential consequences for trade policy, economic development, and even national security. As the tech industry continues to evolve and grow, it is likely that this complex web of international relationships will only become more pronounced. Looking to the future, it is clear that the production of cutting-edge technology will require continued cooperation and collaboration between countries and companies, driving innovation and economic growth in the process. As we move forward, it will be essential to consider the potential risks and challenges associated with this global supply chain, from the potential for trade disruptions to the need for greater transparency and accountability.

As we reflect on the deconstructed iPhone, we are reminded that even the most seemingly mundane objects are often the product of a complex and fascinating global process. The iPhone, often seen as a symbol of modern convenience and connectivity, is in fact a testament to the power of human ingenuity and international cooperation. As we look to the future, it is clear that the tech industry will continue to shape and be shaped by the global economy, driving innovation and growth in the process. And so, as we gaze upon the intricate landscape of the deconstructed iPhone, we are left with a profound and thought-provoking question: what does the future hold for this complex web of global relationships, and how will it shape the world of tomorrow? The answer, much like the iPhone itself, remains a fascinating and intricate puzzle, waiting to be solved.