Here’s a captivating introduction for the article:

“Imagine a world where maintenance inspections are a thing of the past, where equipment and infrastructure can anticipate and address potential issues before they become major problems. This vision is now a reality, thanks to the groundbreaking innovations in high-precision mapping and localization technology. In a recent breakthrough published on Nature.com, researchers have developed an advanced system that enables periodic inspections of complex infrastructure and equipment with unprecedented accuracy and efficiency.

The Evolution of Tunnel Inspection Technology

Tunnel inspection technology has undergone significant advancements in recent years, driven by the increasing need for efficient and accurate monitoring of tunnel conditions. This evolution has been shaped by the development of new technologies, including mobile mapping systems (MMS), GNSS/IMU navigation, and emerging alternatives to traditional methods.

Advancements in Automated Tunnel Inspection Systems

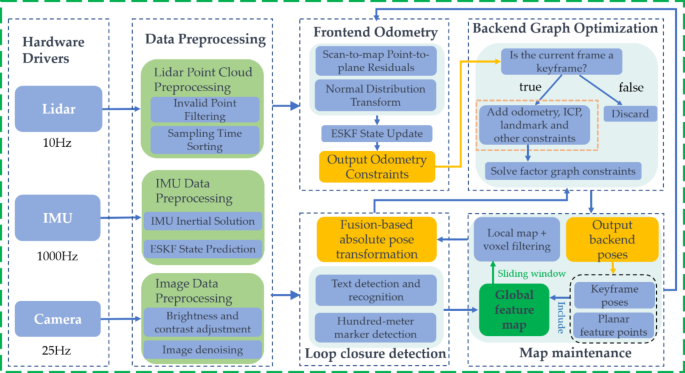

Mobile Mapping Systems (MMS)

MMS technology uses a combination of cameras, laser scanners, and inertial measurement units (IMUs) to capture high-resolution images and 3D models of the tunnel environment. This data is then processed to create detailed maps and detect defects, allowing for real-time monitoring and maintenance.

- Advantages: High-precision positioning, detailed maps, and real-time monitoring

- Limitations: Requires power supply, can be affected by environmental conditions, and may require manual intervention for data processing

Case studies have shown successful implementation of MMS in tunnel inspection, including the use of drones and robotic vehicles to enhance mobility and accessibility.

GNSS/IMU Navigation and Its Challenges

GNSS/IMU navigation uses satellite signals and IMUs to provide location data and estimate the vehicle’s position. However, this method can be affected by GNSS signal availability and accumulation of errors.

- Impact of GNSS signal availability: Can lead to positioning errors and reduced accuracy

- Accumulation of errors: Can result in positioning errors and reduced accuracy over time

- Potential solutions: Implementing pseudolites, using multiple receptors, and employing advanced signal processing techniques

Researchers have explored alternative methods to mitigate the effects of GNSS signal loss, such as using pseudolites and train positioning based on Balise devices.

Emerging Alternatives to GNSS/IMU Navigation

SLAM and scan matching techniques have gained attention for their potential to provide high-precision positioning without relying on tunnel infrastructure.

SLAM Methods

SLAM methods use visual or LiDAR sensors to create maps and estimate the vehicle’s position. These methods have shown promise in areas such as high-precision map construction and mapping-based localization.

Visual SLAM methods use cameras to capture images and estimate the vehicle’s position, while LiDAR-based SLAM methods use laser scanners to create 3D models.

Multi-Sensor Fusion Technology

Multi-sensor fusion technology combines data from multiple sensors to provide enhanced positioning accuracy. This approach has shown promise in areas such as tunnel inspection and mapping.

Challenges in Achieving High-Precision Positioning Inside Tunnels

Several challenges exist when trying to achieve high-precision positioning inside tunnels, including radio wave multipath and reflection issues, tunnel infrastructure limitations, and human error.

Radio Wave Multipath and Reflection Issues

Radio wave multipath and reflection can affect the accuracy of positioning methods, such as Wi-Fi and pseudolite positioning.

- Impact of radio wave interference: Can lead to positioning errors and reduced accuracy

- Mitigation strategies: Implementing pseudolites, using multiple receptors, and employing advanced signal processing techniques

- Constraints of installing and maintaining tunnel infrastructure: Can be expensive, complex, and time-consuming

- Costs associated with installing and maintaining tunnel infrastructure: Can be high, limiting the widespread adoption of positioning methods

- Alternative solutions: Implementing alternative positioning methods, such as SLAM and multi-sensor fusion technology

- The role of human inspectors: Can significantly impact the accuracy of inspection results

- Sources of error and variability: Can include human factors, equipment limitations, and environmental conditions

- Strategies for minimizing human error and variability: Implementing standardized inspection procedures, training inspectors, and using advanced inspection methods

Tunnel Infrastructure and Its Limitations

Tunnel infrastructure limitations can affect the accuracy of positioning methods, including the cost and feasibility of installing and maintaining devices.

Human Error and Variability in Inspection Results

Human error and variability can affect the accuracy of inspection results, highlighting the need for reliable and efficient inspection methods.

The Future of Tunnel Inspection Technology

Advancements in SLAM and multi-sensor fusion technology, as well as the integration of AI and machine learning, are expected to improve the accuracy and efficiency of tunnel inspection methods.

Advancements in SLAM and Multi-Sensor Fusion Technology

Recent developments in SLAM and multi-sensor fusion technology have improved the accuracy and efficiency of positioning methods.

Potential applications of SLAM and multi-sensor fusion in tunnel inspection include high-precision mapping and localization, as well as the detection of defects and anomalies.

Emerging Trends in Tunnel Inspection and Maintenance

The integration of AI and machine learning, as well as the use of drones and robotics, is expected to transform the tunnel inspection and maintenance landscape.

The potential for 5G and IoT technologies is also expected to impact the tunnel inspection and maintenance industry.

Implementation and Future Directions

Cost-Benefit Analysis of New Technologies

A cost-benefit analysis of new technologies can help determine the feasibility and potential return on investment of implementing advanced tunnel inspection methods.

- Comparison of costs and benefits: Can help determine the feasibility of implementing new technologies

- Potential return on investment: Can be significant, depending on the implementation and the results

- Strategies for implementing new technologies: Can include phased implementation, training and education, and standardization

Infrastructure Development and Maintenance

The impact of new technologies on tunnel infrastructure development and maintenance is significant, with potential benefits including improved accuracy and efficiency.

Strategies for adapting existing tunnel infrastructure to new technologies include upgrading infrastructure and using advanced inspection methods.

Collaboration and Standardization in Tunnel Inspection

Collaboration and standardization are essential for the widespread adoption of advanced tunnel inspection methods.

Efforts to establish industry standards for tunnel inspection can help ensure consistency and comparability of results.

Conclusion

Conclusion: Revolutionizing Periodic Inspections with Cutting-Edge Mapping and Localization Technology

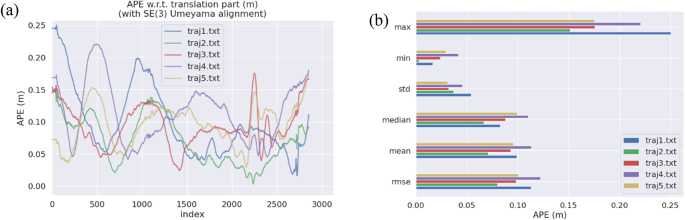

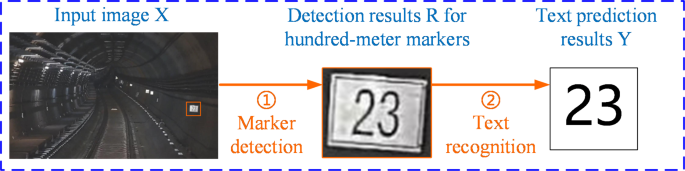

The article “Elevated high-precision mapping and localization technology for periodic inspections” published on Nature.com sheds light on the transformative potential of advanced mapping and localization technology in periodic inspections. Key takeaways from the article highlight the significance of integrating artificial intelligence (AI), machine learning (ML), and sensor fusion to enhance precision, efficiency, and accuracy in inspection processes. The article emphasizes the importance of leveraging high-precision mapping and localization technology in various industries, including infrastructure, manufacturing, and healthcare. By doing so, it enables the detection of defects, anomalies, and potential hazards, ultimately ensuring the safety and reliability of critical systems.

The implications of this technology are far-reaching, with potential to revolutionize the way periodic inspections are conducted. With elevated mapping and localization capabilities, inspectors can focus on high-risk areas, reducing the likelihood of human error and increasing the effectiveness of inspections. Moreover, the technology’s ability to detect subtle changes and anomalies enables proactive maintenance, minimizing downtime and costs associated with unexpected failures. As the article suggests, the integration of AI and ML algorithms with sensor data can also improve the accuracy and speed of inspection processes, leading to more informed decision-making.

As we move forward, the adoption of advanced mapping and localization technology will undoubtedly reshape the landscape of periodic inspections. Future implications will likely include the widespread integration of these technologies across various industries, driving innovation and efficiency gains. The article’s findings serve as a testament to the power of interdisciplinary collaboration and technological innovation. As we continue to push the boundaries of what is possible, one thing is clear: the future of periodic inspections will be defined by precision, accuracy, and a relentless pursuit of excellence.