“Homegrown Luxury: The Hidden Cost of a ‘Made in the USA’ iPhone” As the world watches the ongoing trade tensions between the United States and China, Apple’s decision to manufacture a ‘Made in the USA’ iPhone has sparked a heated debate about the true cost of patriotism. Behind the gleaming screens and sleek designs of the world’s most coveted smartphones lies a complex web of economics, politics, and manufacturing costs. In this exclusive deep-dive, we’re about to uncover the shocking truth: just how much would a USA-made iPhone really cost? Dive with us into the world of economic nationalism and discover the price of putting America first.

The Practical Aspects of a “Made in the USA” iPhone

Foxconn and Contract Manufacturing

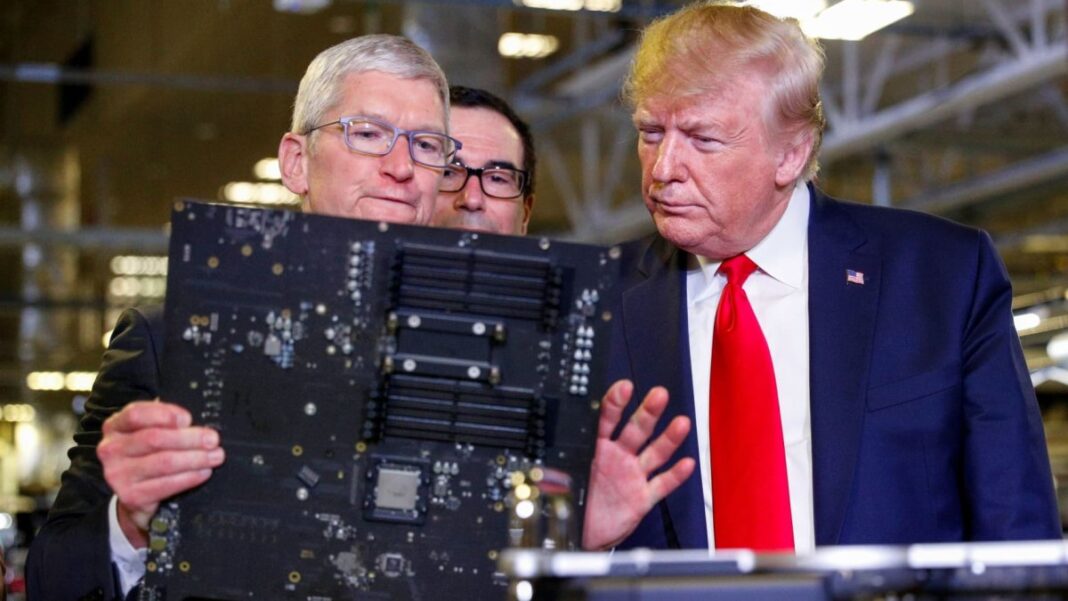

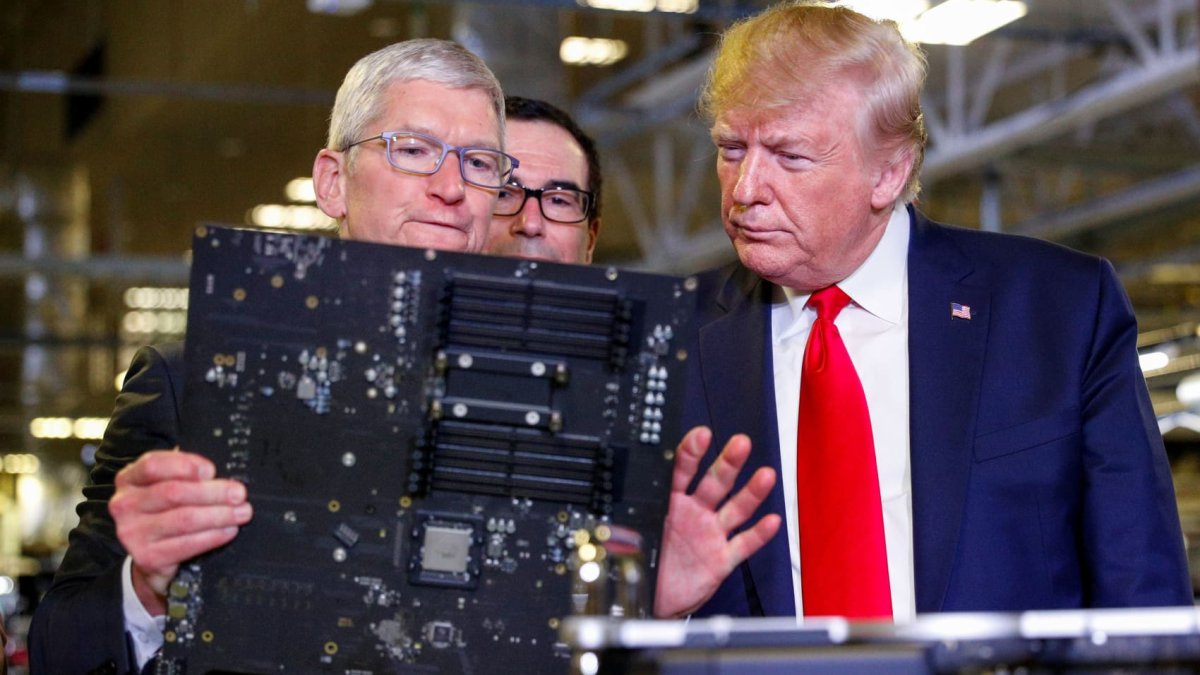

At the heart of the iPhone’s manufacturing process lies a complex network of suppliers and contract manufacturers, with Foxconn playing a pivotal role. Foxconn, formally known as Hon Hai Precision Industry Co., is the largest contract manufacturer in the world and has been Apple’s primary production partner for many years. The company’s extensive experience and efficient production lines have allowed it to maintain the delicate balance between cost and quality that Apple demands. However, the intricate supply chain and manufacturing process pose significant challenges for relocating production to the United States.

The Current Manufacturing Process

The current manufacturing process for iPhones is highly specialized and optimized for efficiency. This process involves a series of steps from component assembly to final testing, all of which are designed to ensure high output and minimal costs. The assembly line in Foxconn’s factories in China, for example, can produce millions of iPhones per day, a feat that is unparalleled in the technology sector. Each step in the process is meticulously planned and executed, making it difficult to replicate such a streamlined operation in a new location.

The Challenges of Establishing a US-Based Manufacturing Plant

Establishing a manufacturing plant in the United States for iPhones would face numerous challenges. One of the primary hurdles is the cost of labor. Wages in the US are significantly higher than those in China, which would translate into higher production costs. According to a report by Unionjournalism, the labor wages alone could increase the cost of an iPhone by 25%, making it a more expensive product for consumers.

Another significant challenge is the lack of an existing workforce skilled in the specific tasks required for iPhone assembly. In China, Foxconn has developed a vast workforce over the years, trained in the precise assembly processes needed for Apple products. Building a similar workforce in the US would require substantial investment in training and infrastructure. Additionally, the logistics of setting up such a large-scale manufacturing operation from scratch, including the establishment of the necessary supply lines and infrastructure, would be a massive undertaking.

The Impact on Apple’s Supply Chain

The Current State of Apple’s Supply Chain

Apple’s current supply chain is a marvel of modern logistics, with components sourced from all over the world and assembled in China. The company has worked closely with suppliers to ensure a steady flow of parts, minimizing disruptions and optimizing costs. This level of coordination and efficiency is a result of years of collaboration and fine-tuning, achieved partly because of the proximity of suppliers in China and the availability of skilled labor.

The Challenges of Transitioning to a US-Based Supply Chain

Moving the supply chain to the US would pose significant logistical and financial challenges. The supply chain for iPhones involves a complex web of suppliers and parts, many of which are specialized and sourced from suppliers around the world. Establishing a new supply chain in the US would require relocating or finding new suppliers, a process that would not only be costly but could also introduce delays and potential inefficiencies. Moreover, the tariffs on imported components would add an additional layer of cost, making the production of iPhones in the US significantly more expensive.

The Implications of a “Made in the USA” iPhone

The Impact on Consumers

The Potential Price Increase

One of the most significant implications of a “Made in the USA” iPhone would be a substantial increase in price for consumers. According to a study by Unionjournalism, the labor costs alone could drive up the price of an iPhone by 25%. This increase does not account for additional expenses such as tariffs on imported components, higher utility costs, and the cost of setting up new manufacturing facilities. Analysts predict that the price of a new iPhone could rise to around $3,500, making it a luxury item for most consumers.

The Impact on Consumer Demand

With the potential for a significant price hike, consumer demand could be heavily impacted. The current pricing strategy of Apple is highly competitive, and a price increase could deter many consumers, especially those who are price-sensitive. However, the price increase could also create a niche market for consumers who are willing to pay a premium for a “Made in the USA” label, driven by patriotism or a desire to support domestic manufacturing. This shift could alter the competitive landscape for Apple, forcing it to reassess its pricing and marketing strategies to maintain market share.

The Impact on Apple’s Competitors

The Competitive Landscape

The competitive landscape for smartphone manufacturers is highly dynamic, with major players such as Samsung, Google, and Xiaomi constantly vying for market share. A significant increase in the cost of iPhones, driven by domestic manufacturing, could give competitors an edge. Samsung, for instance, could leverage its more affordable pricing strategy to capture a larger market share, especially among budget-conscious consumers. The shift in pricing could also prompt competitors to push for even more aggressive pricing and innovation strategies to capitalize on Apple’s higher costs.

The Potential Impact on Apple’s Market Share

The potential price increase of the iPhone due to “Made in the USA” manufacturing could have a significant impact on Apple’s market share. If Apple decides to pass on these increased costs to consumers, it could lose market share to other competitors with more cost-effective manufacturing models. Conversely, if Apple absorbs some of these costs to maintain current pricing, it could severely impact its profit margins. Analysts at Unionjournalism predict that a significant price hike could lead to a decline in sales, particularly in markets where affordability is a major factor in purchasing decisions. This might force Apple to explore alternative pricing strategies and potentially reconsider its commitment to domestic manufacturing if it cannot sustain the increased costs.

Conclusion

Conclusion: The True Cost of ‘Made in the USA’ iPhones

The recent analysis by CNBC on the potential cost of a ‘Made in the USA’ iPhone has shed new light on the complexities of manufacturing and pricing. The article reveals that producing iPhones in the United States could increase their price by as much as $243, a significant premium over the current cost. This is largely due to the higher labor and production costs associated with domestic manufacturing, as well as the need for Apple to maintain its profit margins. By examining the production costs, tax implications, and consumer demand, the article highlights the intricate web of factors influencing the pricing of a ‘Made in the USA’ iPhone.

The significance of this analysis extends beyond the iPhone, as it reflects the broader conversation around globalization, trade policies, and the role of domestic manufacturing in the tech industry. As the article suggests, the cost implications of producing in the United States could have far-reaching consequences for consumers, manufacturers, and policymakers. Furthermore, the analysis raises questions about the potential for job creation, wage growth, and economic development in the United States, should Apple choose to shift its manufacturing operations domestically. As the global economy continues to evolve, it will be essential for policymakers, business leaders, and consumers to engage in a nuanced discussion about the benefits and drawbacks of ‘Made in the USA’ production.

In conclusion, the ‘Made in the USA’ iPhone would likely come with a hefty price tag, but this analysis also underscores the larger implications of domestic manufacturing on the economy, jobs, and consumer choice. As we navigate the complexities of globalization and trade policy, it is essential to weigh the costs and benefits of ‘Made in the USA’ production. Will Apple’s decision to produce in the United States spark a new wave of domestic manufacturing, creating jobs and growth opportunities? Or will the higher costs of production outweigh the benefits, relegating the ‘Made in the USA’ iPhone to a luxury item for the affluent? The answers to these questions will shape the future of the tech industry and the global economy.